Services

Our services

Our company has always been focused on offering a service to meet all our clients' needs, from design and prototyping to mould production.

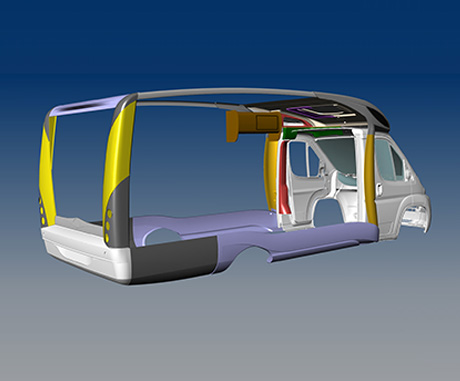

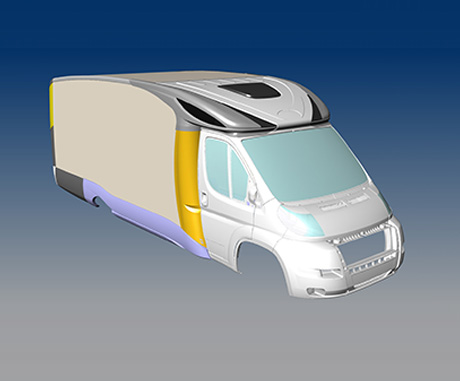

Planning

We use dedicated software to shape and design your ideas. CAD design systems have greatly enhanced the designer's creativity, fostering high levels of quality and productivity.

Even a manual drawing or sketch allows us to develop a final design, ready to be manufactured on an industrial scale. We can offer an appropriate co-design and co-engineering service to style and manufacture new designs or update existing ones.

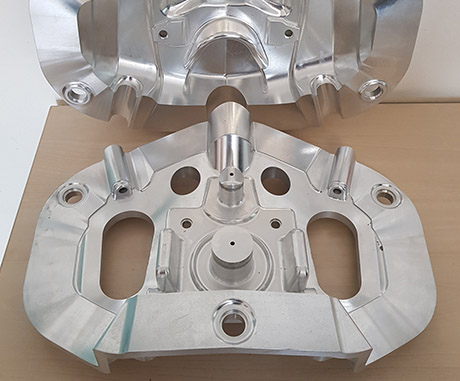

Prototyping

Although three-dimensional graphics are of great help, sometimes a virtual design is not enough. We therefore create the physical model to be seen, touched, and tested, to systematically eliminate any anomalies.

We develop conceptual prototypes for style checks and ergonomic studies, functional prototypes to test product feasibility, assembly tests and functionality.

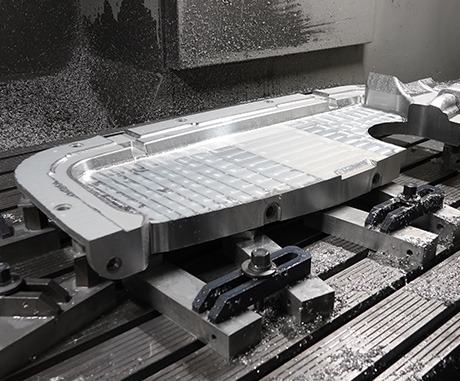

Conceptually, rapid prototyping is the most cost-effective system allowing complex designs to take material form, including in small-batch production, before being manufactured on an industrial scale. Our 5-axis CNC machining centres, combined with the manual skills of our model makers, allow us to develop full-scale parts, including some of considerable dimensions, in a short space of time.

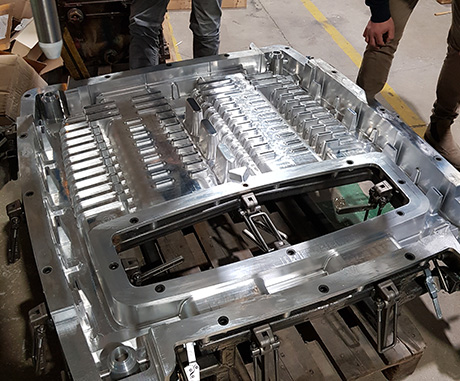

Thermoforming moulds

The vacuum thermoforming moulding process involves the deformation of the polymer sheet by a heating process and subsequent adaptation to the mould (form) with air extraction through small suction holes in the mould.

Area Stampi designs and manufactures thermoforming moulds in wood or resin for samples and small-batch production, in aluminium for sustained production.

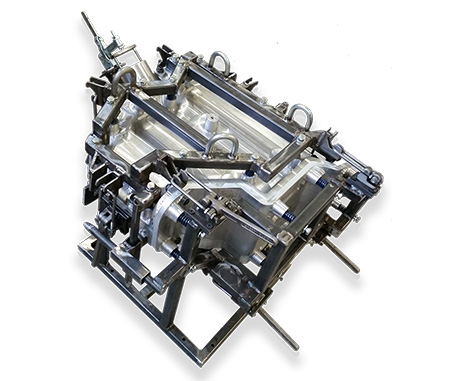

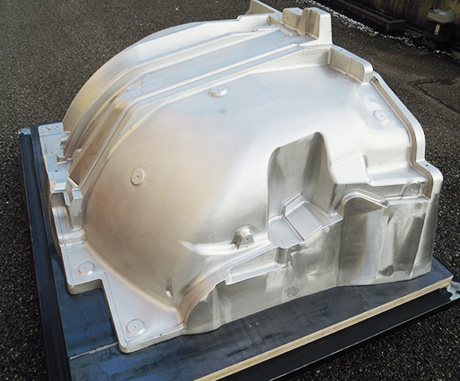

Rotomoulding (rotational) moulds

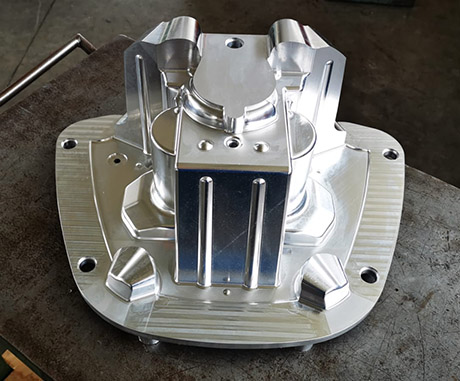

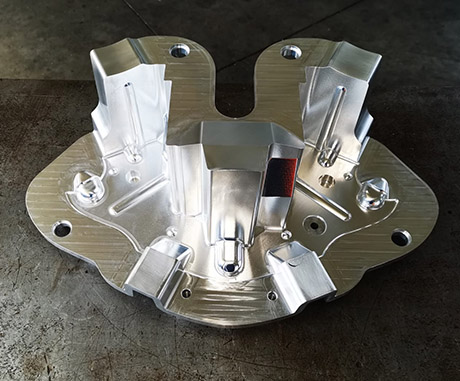

Area Stampi has been active in this sector for several years, which offers considerable economic advantages when purchasing equipment, especially for limited production runs and medium to large-sized products.

Rotational moulding technology allows the production of internally hollow parts used in a variety of industries: automotive, furniture, lighting, playgrounds, sanitary, medical, decorative, nautical, agricultural, wellness, etc.

Usually, the material used is PET or PETG, which is highly resistant to mechanical and atmospheric stress and ideal for indoor and outdoor environments.

Area Stampi manufactures these mould types, carving them directly from solid aluminium blocks machined using CNC machining centres.